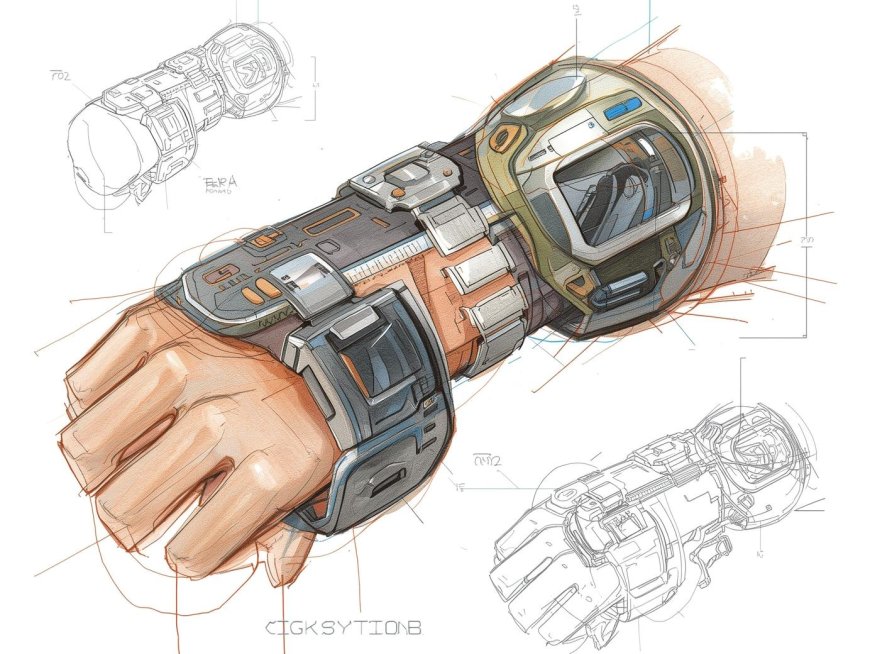

Battery Life & Durability: Engineering Considerations for Rural Use

A practical, Africa-focused engineering playbook for wearable biosensor teams building devices for rural settings. Covers power budgeting and step-by-step battery calculations, low-power radio tradeoffs (BLE / LoRaWAN / NB-IoT), solar and swap strategies, ruggedization (IP/MIL-STD), thermal and humidity testing, field maintenance workflows for CHWs, procurement specs, safety/standards (IEC 62133), and an acceptance-test checklist investors and Ministries expect. Includes worked examples and APA references with live links.

Short brief: If your biosensor dies at a boda stop or delaminates after one rainy season, nobody cares how smart the algorithm is. Rural settings in Africa impose a brutal combination: intermittent power, dust, heat, sweat, long logistics chains and sometimes long gaps between maintenance visits. This guide gives engineers, product managers and implementers a practical, down-to-earth (and slightly cheeky) checklist to design, test and procure wearables that keep working where they’re needed most.

Expect: one rib-cracking field anecdote, an explicit battery-capacity worked example (digit-by-digit), radio tradeoffs, ruggedness specs you should demand, test protocols, a CHW maintenance workflow, and procurement wording you can paste into an RFQ.

Opening anecdote (field-tested and humble)

A startup shipped 1,200 “clinical-grade” wearables to clinics across a county. In week two, half of them returned with “no charge” complaints — not because the batteries were bad, but because devices were set to aggressive debugging telemetry that woke every 30 seconds. The fix was simple: tune duty cycles, add a power-fail safe-mode, and teach CHWs how to swap batteries. The lesson: battery life is both a technical and a human problem.

Why this matters — the hard constraints in rural African contexts

Rural health settings typically include: intermittent grid power or none at small clinics, high daytime temperatures, wide humidity swings, lots of dust, occasional flooding, long transport times for spares, and users who expect devices to “just work” for weeks. WHO and related guides emphasize designing for these low-resource settings to ensure health technologies are usable, maintainable and safe. World Health Organization

Engineering choices you make early (battery chemistry, radio, duty cycle, enclosure, charging strategy) determine total cost of ownership, field uptime, and user trust. Below are practical decisions and how to test them.

Core engineering principles (short list)

-

Design for long sleep: minimize average current by maximizing sleep time and keeping active bursts short.

-

Measure energy per operation: compute µAh/measurement + µAh/transmit and budget battery capacity with safety margin.

-

Choose radio to match range & duty: BLE for smartphone tethering; LoRaWAN or NB-IoT for long-range uploads without a phone — each with distinct energy profiles. Diva Portal+1

-

Ruggedize to environmental reality: target IP66–IP68 and consider MIL-STD drop/vibration if logistics are rough. Samsung Business Insights

-

Make charging & maintenence local-friendly: solar + USB charging, hot-swap batteries, or charger hubs at CHW centres. WHO’s energizing-health work shows power reliability is the chokepoint for device uptime. WHO

Battery basics & safety standards you must cite in spec

-

Use rechargeable chemistries (Li-ion / Li-polymer) only if packaging and battery management meet IEC 62133 safety requirements; for replaceable primary cells (AA/CR123), check compatibility and rugged holder design. IEC 62133 covers safe operation and testing of portable batteries used in devices. FDA Access Data+1

-

If devices will be stored hot (e.g., >40°C), validate capacity fade vs temperature in your stability tests — battery capacity drops with temperature extremes and calendar age, and heat accelerates degradation.

Power budgeting — step-by-step worked example (investors expect to see math)

We’ll compute the required battery capacity for a wearable that:

-

wakes every 10 minutes to sense and transmit;

-

active sensing + transmit takes 5 seconds per wake and draws 50 mA during that active window;

-

sleeps the rest of the time at 5 µA (0.005 mA);

-

target field life between charges = 45 days (design requirement);

-

target safety margin = 20% (for ageing, temperature, degradation).

We must compute the average current and then convert to battery mAh required.

Step-by-step arithmetic (digit by digit):

-

Determine wakes per hour:

-

One wake every 10 minutes → 60 minutes ÷ 10 minutes = 6 wakes per hour.

-

-

Active seconds per hour:

-

Each wake is 5 seconds → 6 × 5 = 30 seconds per hour.

-

-

Convert active seconds to fraction of hour:

-

1 hour = 3600 seconds.

-

Active fraction = 30 ÷ 3600.

-

Perform division: 3600 goes into 30 → 30 ÷ 3600 = 0.0083333333… (that is 1/120).

-

-

Active contribution to average current (mA):

-

Active current = 50 mA.

-

Active average = 50 × 0.0083333333 = 0.4166666665 mA.

-

(Fewer rounding steps: 50 × 1/120 = 50/120 = 5/12 ≈ 0.4166666667 mA.)

-

-

Sleep contribution to average current:

-

Sleep current = 0.005 mA.

-

Sleep fraction = 1 − 0.0083333333 = 0.9916666667 (hours).

-

Sleep average = 0.005 × 0.9916666667 = 0.0049583333 mA.

-

-

Total average current (mA):

-

Total = active average + sleep average = 0.4166666667 + 0.0049583333 = 0.42162499999999996 mA.

-

Round sensibly → 0.422 mA.

-

-

Required battery capacity (mAh) for desired runtime (hours):

-

Desired runtime: 45 days. Convert to hours: 45 days × 24 hours/day = 1,080 hours.

-

Required capacity (ideal) = average current × hours = 0.422 mA × 1,080 h.

-

Multiply: 0.422 × 1,080. First 0.422 × 1000 = 422.0; 0.422 × 80 = 33.76; sum = 455.76 mAh.

-

So ideal capacity = 455.76 mAh.

-

-

Add safety margin for degradation & temperature (20%):

-

Margin factor = 1 + 0.20 = 1.20.

-

Capacity with margin = 455.76 × 1.20 = 546.912 mAh → round up to ≈ 550 mAh.

-

Result: Choose a battery ≥ 550 mAh (at nominal voltage) to meet the 45-day target given these assumptions. If you pick a 500 mAh cell you’d miss the target; a 600–1000 mAh battery gives extra headroom for colder/ hotter months and firmware updates.

Notes & caveats:

-

Real device average current will differ if radios (BLE advertising, reconnection, retransmits) or sensors (ECG front-end, ADC) consume more during active windows — measure these in lab and use measured currents, not optimistic datasheet figures.

-

Batteries ageing, charging inefficiency, and temperature can reduce usable capacity by 10–30%—hence the safety margin. Use field measurements to re-tune assumptions.

-

If frequent firmware updates are expected, budget extra for higher duty or OTA windows.

(References on battery run-time formulas and practical considerations are standard; see battery calculators and device engineering notes.) Orient Display+1

Radio & data strategy — pick the right connectivity for power vs reach

Short cheat-sheet:

-

BLE (Bluetooth Low Energy)

-

Best when paired with user smartphone for uplink; extremely low energy for short bursts; but requires the patient to have a powered smartphone present and cooperate. Good for CHW-assisted sync. PREDICTABLE DESIGNS

-

-

LoRaWAN (LPWAN)

-

Long range, low energy uplink; excellent for dispersed rural nodes that can reach a nearby gateway. Ideal when small payloads (periodic vitals summary) are acceptable. Gateway coverage may be limited — consider deploying community gateways. LoRaWAN typically uses far less energy per transmit vs NB-IoT. Diva Portal

-

-

NB-IoT / LTE-M

-

Cellular LPWA variant: better in existing cellular infrastructure areas and offers deeper indoor coverage; higher energy for attach procedures than LoRa but works with existing telco networks; subscriptions and SIM management add cost. Use when direct cloud connectivity is essential and range/data needs warrant it. Lansitec+1

-

Design rule: match the radio to the expected connectivity model (phone tether vs gateway vs SIM): LoRaWAN for battery-first long range without phones; BLE for phone-centric UX; NB-IoT for robust telco-backed reach but plan for higher energy and SIM logistics.

Charging & power delivery strategies that work in the field

-

Solar micro-chargers (USB) — small foldable solar chargers feeding a USB powerbank at CHW hubs. Durable, cheap ($10–$40), but require a charging routine and are weather dependent. WHO notes electrification is uneven — solar solutions are pragmatic in many clinics. WHO

-

Swappable battery packs — design devices with user-replaceable packs (AA/18650 or proprietary swappable modules) and keep spare pools at CHW centres. This reduces downtime but adds logistics for spare tracking and safe disposal.

-

Hot-swap external battery pack — attach a small removable battery pack that can be swapped in under 10 seconds (avoid exposing inner electronics to dust/water while swapping).

-

Reagent-rental / hub charging — if devices are clinic/hub-based, provide instrument charging docks with UPS. Central charging reduces per-device battery complexity.

-

Energy harvesting — niche: kinetic or thermoelectric harvesters are low-power and can extend life but rarely supply full load for active sensing/transmit. Consider only as supplement. PMC

Operational tip: pick a charging model that matches workforce workflows — CHWs with weekly visits can swap batteries; patients without reliable transport need devices that last multiple weeks between charges.

Ruggedization — make the enclosure survive real life

Minimum hardware spec checklist for rural wearables:

-

Ingress protection: target IP66 (dust-tight + protection against powerful water jets) as baseline; aim IP67/IP68 if immersion risk exists. Test per IEC procedures. Samsung Business Insights

-

Shock & drop: design to survive 1.0–1.5 m drops on concrete; consider MIL-STD-810H shock/vibration test if logistics are especially harsh. Samsung Business Insights

-

UV & chemical resistance: use UV-stabilized plastics and coatings; sweat/soap resistance for wearables in contact with skin.

-

Straps & attachments: secure fastening (locking buckle, medical-grade silicone) with standard sizes and spares.

-

Sealed connectors / magnetic charging: avoid exposed pogo pins unless in tough sealed recesses; magnetic pogo with sealed gasket is often best.

-

Conformal coating for PCBs to reduce humidity-related corrosion and maintain sensor reliability.

Test all of the above in accelerated environmental chambers and in field pilot (see test protocol below).

Field and lab testing protocols (what investors/regulators will want to see)

-

Thermal cycling (climate chamber)

-

Cycle device between −10°C and +55°C for X cycles (e.g., 10 cycles) to test seals and battery behaviour. Record boot failures, capacity shift and casing deformation.

-

-

High-humidity soak

-

85% RH at 40°C for 48–168 hours to reveal condensation problems.

-

-

Ingress testing (IP test)

-

Dust chamber (per IP6x) and water jets + immersion tests per target rating (IP66/IP67/IP68).

-

-

Drop & shock testing

-

1.5 m drop on concrete in six orientations; vibration sweep per MIL-STD if possible.

-

-

Solar & UV exposure

-

UV lamp exposure equivalent to months of sun to check plastics and straps for embrittlement.

-

-

Battery abuse and safety tests (performed by battery module supplier)

-

Short circuit, overcharge, overdischarge, thermal runaway tests per IEC 62133 and supplier certificates.

-

-

Real-world soak pilot

-

Deploy n = 20 units to CHWs for 60 days; log uptime, battery swaps, failure modes, strap breaks, and user feedback.

-

Document all tests, failures, corrective actions and re-tests.

Maintenance & logistics — CHW workflows that keep devices alive

A practical CHW maintenance cycle (weekly/monthly cadence):

-

Daily (patient encounter): visual check, strap tension, quick touch test, sync data if phone present.

-

Weekly (CHW hub visit): top-up charging or battery swap; inspect seals; run quick self-test (device performs boot and sensor self-check).

-

Monthly (supervisor): firmware updates via clinic hub; run calibration checks against portable reference; replace consumables/straps.

-

Adverse event: immediate stop and tag device if battery swelling or ingress observed; return to central facility.

Keep a spare-pool ratio: 1 spare per 8–10 deployed devices recommended where logistics are slow. Track spares in LMIS.

Procurement spec lines you can paste into RFQ

-

Battery: “Rechargeable Li-ion/polymer pack, IEC 62133 certified, nominal capacity ≥ 550 mAh (or specify target), integrated BMS with over-charge / over-discharge / short-circuit protection; operating temp −10°C to +55°C; storage temp −20°C to +45°C.” FDA Access Data

-

Enclosure: “Ingress protection minimum IP66; device to survive 1.5 m drop in six orientations; UV-stabilized polymer; straps medical-grade silicone with tensile rating X N.”

-

Charging: “Magnetic sealed pogo or USB-C with waterproof gasket; support for solar charging via standard USB input; charge time ≤ 4 hours with 5V/2A input.”

-

Connectivity: “Device must support BLE 5.0 low-energy and optional LoRaWAN module (region band EU868/AS923/US915 as per deployment) with documented per-transmission energy profile.”

-

Warranty & spares: “24-month warranty; spare part availability within 30 days; supply of X spare straps and Y spare battery packs per 100 units.”

Cost tradeoffs and lifecycle economics

-

Bigger battery → heavier device, higher cost, possibly lower acceptance for wearables. Small devices with weekly charging may succeed if charging routine is easy; for unattended nodes, buy larger cells and weatherproofed enclosures.

-

Replaceable AA or 18650 cells simplify logistics where rechargeable charging is impossible, but create waste and ecological issues. Consider local recycling partners.

-

Factor in total cost of ownership: device cost + spare pool + charging infrastructure + logistics + replacement rate over 3–5 years.

Safety, disposal & regulatory notes

-

Batteries are hazardous waste: plan collection and safe recycling. IEC and local waste rules apply. IEC 62133 and national regulations guide safe battery integration and handling. FDA Access Data

-

If device is a medical device, the QMS (ISO 13485) and device electrical safety (IEC 60601 family where applicable) govern testing and documentation — involve regulatory early. PMC

Quick field acceptance test (FAT) checklist — what to run before signing off a batch

-

Battery nominal capacity verification (sample 10 units): measured mAh ≥ spec (at 25°C).

-

Run simple duty cycle test for 7 days to confirm expected days between charge.

-

IP ingress demo: splash test and dust exposure.

-

Strap tensile test on samples.

-

Connectivity check across at least 3 deployment sites (BLE, LoRa or NB-IoT ping).

-

Visual inspection for glue/seal integrity and manufacture defects.

-

Firmware version freeze & OTA test.

-

COA and IEC 62133 battery certificate included.

Short deployment vignette (how a good program works)

A Kenyan county health office piloted 300 maternal-care wearables with 12 CHWs. Devices used BLE for daily sync via CHW smartphone, 600 mAh batteries, and a solar charging hub at the sub-county clinic. CHWs swapped batteries weekly during routine visits, and central monitoring dashboards flagged devices that missed two syncs. Failure rate in 6 months was <4% (strap wear and one batch of damaged pogo pins), and the logistic cost per device/year was lower than anticipated because downtime was minimal. The pilot’s success hinged on simple charging routines and a spare pool at the hub.

References (APA format — live links)

-

World Health Organization. (2024). Compendium of innovative health technologies for low-resource settings. https://www.who.int/publications/i/item/9789240095212. World Health Organization

-

International Electrotechnical Commission. (n.d.). IEC 62133: Requirements for portable sealed secondary cells and for batteries... (referenced via FDA standards list). https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfstandards/detail.cfm?standard__identification_no=32632. FDA Access Data

-

Arandia, N. (2022). Embedded Sensor Systems in Medical Devices. Journal/Article — technical review on standards and battery safety. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9781231/. PMC

-

Tan, L. (2020). Comparison of LoRa and NB-IoT in Terms of Power Consumption (thesis). https://www.diva-portal.org/smash/get/diva2%3A1451892/FULLTEXT01.pdf. Diva Portal

-

Samsung Insights. (2020). IP68 and MILSPEC: How they protect your smartphone investments. https://insights.samsung.com/2020/05/04/ip68-and-milspec-how-they-protect-your-smartphone-investments/. Samsung Business Insights

-

Orient Display. (2025). How to estimate battery life for your device. https://www.orientdisplay.com/how-to-estimate-battery-life-for-your-device-even-with-sleep-modes/. Orient Display

-

World Health Organization. (2022). Energizing Health: Accelerating electricity access in health-care facilities. https://cdn.who.int/media/docs/default-source/air-pollution-documents/air-quality-and-health/final_energizing_health_full-report_sm.pdf. WHO

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0